Diamonds are among the oldest natural materials on Earth, formed over billions of years deep beneath the surface under extreme heat and pressure.

This rare combination of time and geology transforms carbon into crystals prized for their hardness, brilliance, and durability.

Long before a diamond reaches a jewelry store, it must first be discovered and extracted through a highly structured industrial process.

Understanding how diamonds are mined requires looking beyond the finished stone. Diamond mining involves advanced geological surveys, large-scale excavation, and precise diamond extraction methods designed to separate rough diamonds from vast amounts of rock.

Each stage affects quality, availability, and environmental impact. As awareness of responsible sourcing grows, understanding the origin of diamonds has become an essential consideration when considering lab-grown diamonds as an alternative to natural diamonds.

Let us walk through how diamonds move from volcanic rock deep within the Earth to polished stones displayed in jewelry stores.

Where Diamonds Actually Form

Diamonds do not form near the Earth’s surface. They originate deep within the mantle, typically at depths of 140-190 kilometers (about 90-120 miles), where temperatures of 900–1,300°C (1,650–2,400°F), and pressure is intense enough to alter the atomic structure of carbon. Under these conditions, carbon atoms bond in a rigid crystal lattice, creating diamonds over millions to billions of years.

These diamonds remain trapped deep underground until powerful volcanic activity pushes them closer to the surface. Rapid ascent through kimberlite pipes is essential, as slower rates (below ~3-6 m/s) can expose diamonds to conditions promoting graphitization or resorption.

The speed of these eruptions is critical. If the ascent were slow, the diamonds would degrade back into graphite before reaching stable ground.

Once the magma cools, diamonds become locked inside solid volcanic rock. Over time, erosion may release some stones into surrounding soil, riverbeds, or coastal areas, where they can later be recovered through secondary mining methods.

This natural process explains why diamonds are found in both deep volcanic deposits and surface-level sediments, shaping how and where diamond mining operations begin.

How to find diamonds in the ground?

Finding diamonds is expensive and usually unsuccessful. Over the last 140 years, geologists sampled nearly 7,000 kimberlite pipes, with about 1,000 diamondiferous and only around 60 economically viable for large-scale mining, roughly 1 in 100-200 pipes viable, fewer than 1% profitable (Source: Natural Diamond Council).

The search starts with geological surveys. Teams study ancient volcanic activity patterns using satellite imagery to spot circular features that might indicate eroded volcanic pipes. Airborne surveys measure magnetic and gravitational potential since kimberlite has distinct signatures.

When surveys identify promising areas, crews collect samples. They test stream sediments for indicator minerals like garnets and chromites that typically accompany diamonds. If these markers show up, there's likely a kimberlite source nearby.

Then comes drilling. Core samples from hundreds of feet down reveal whether kimberlite exists and whether it contains diamonds in viable concentrations. Teams process these cores to recover any diamonds and calculate how many carats per ton they can expect.

Modern exploration uses LiDAR mapping, geochemical analysis, and machine learning to predict where undiscovered pipes might exist. But even with all this technology, companies might spend a decade and tens of millions finding nothing economically viable.

The Four Main Mining Methods

Diamond extraction depends largely on where the deposits are located. Once identified, specific mining methods are used to recover the stones efficiently and safely.

Method 1: Open-Pit Mining

Open-pit mining is used when diamond deposits are near-surface, typically up to 1,000 meters (~3,300 feet), as seen in major operations like Mir mine (525m) or Udachnaya (630m+). Large sections of land are excavated in stages, creating wide pits that grow deeper over time. Heavy machinery extracts layers of rock to access kimberlite ore, making this method efficient for high-volume extraction but highly disruptive to the landscape.

These operations create permanent landscape changes, which is one reason many buyers now prefer options that avoid mining altogether.

A large portion of diamond production comes from open-pit operations because it is the most economical method for extracting large, shallow diamond deposits.

Method 2: Underground Mining

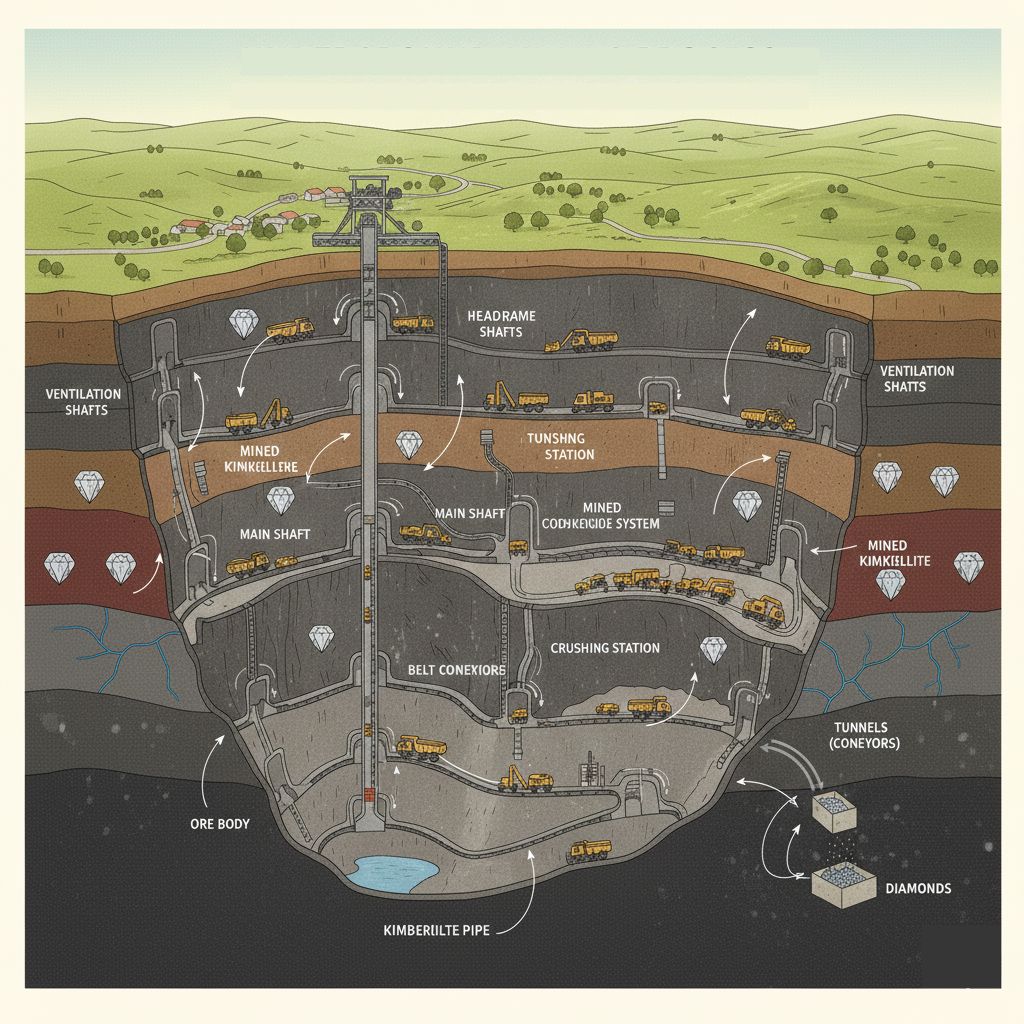

Underground mining is carried out when deposits extend too deep for open-pit extraction. Companies sink vertical shafts to the ore, sometimes reaching 3,000 feet or more. Horizontal tunnels branch out to access the kimberlite.

They use block caving or shaft mining with controlled drilling and blasting. The safety requirements are strict, including ventilation systems, rock bolts to prevent collapses, and automated drilling to reduce human exposure.

Method 3: Alluvial Mining

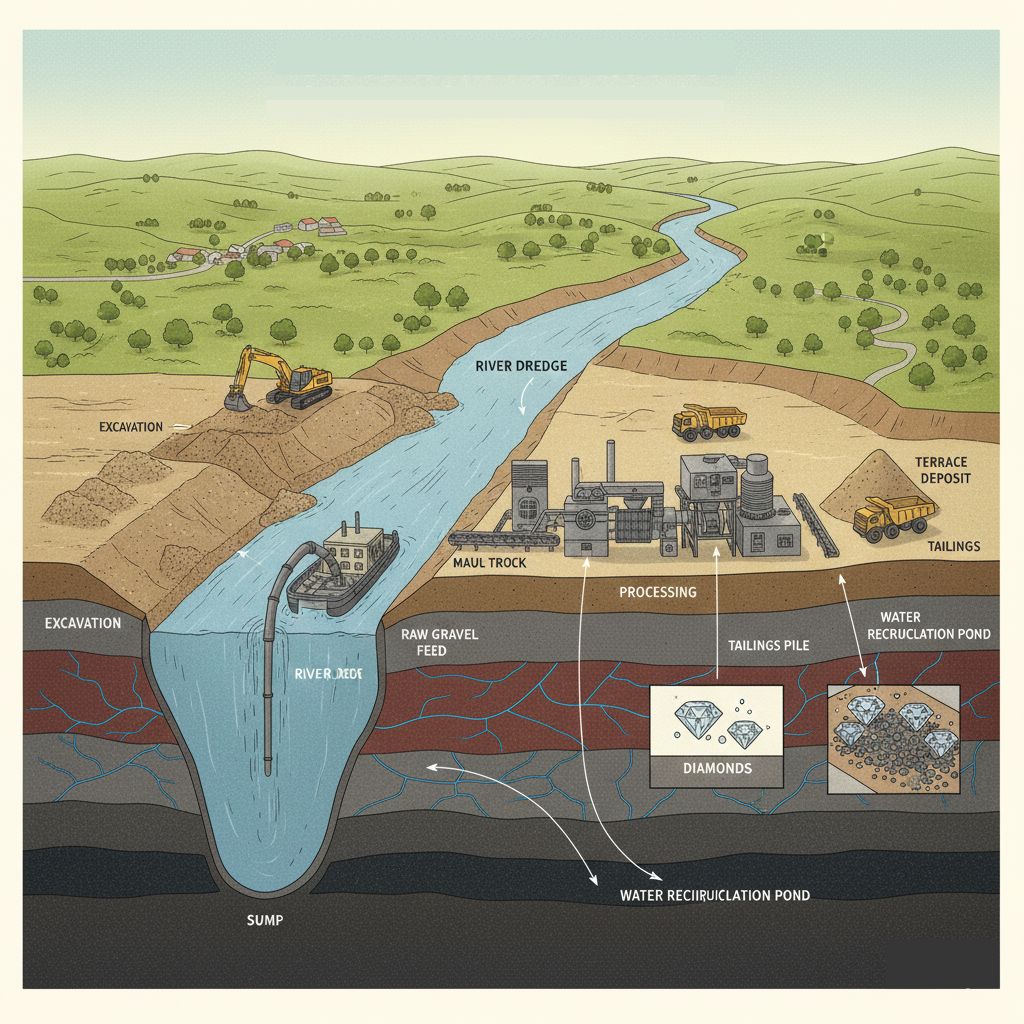

Alluvial mining targets diamonds that are found when rivers erode kimberlite pipes and carry diamonds downstream, creating alluvial deposits. Small-scale operations use pans and sieves to separate diamonds from river sediment. Industrial operations deploy bulldozers, washing plants, and screening equipment.

Method 4: Marine Mining

Marine mining extracts diamonds that washed into the ocean millions of years ago, now sit in underwater gravel beds. Specialized ships vacuum up seabed sediment, process it onboard to extract diamonds, then return waste material to the ocean.

This method produces high-quality stones because ocean processes concentrate denser diamonds in gravel beds, often yielding high-quality gemstones across varied sizes. But it requires expensive, specialized vessels.

How Diamonds Are Separated From Rock

After diamond-bearing ore is extracted from the ground, it goes through a multi-step processing system designed to isolate rough diamonds from tons of surrounding rock. This separation process relies on the physical properties that make diamonds unique, including their density and ability to reflect certain wavelengths.

The first step involves crushing the ore into smaller fragments. This makes it easier to release diamonds that are still embedded in solid rock. The crushed material is then mixed with a dense liquid during a process known as dense media separation using a ferrosilicon slurry suspension (density ~3.52 g/cm³, matching diamonds), where heavier diamonds sink.

Next, advanced sorting technologies are used to improve accuracy. X-ray and laser-based systems detect diamonds based on how they react to energy exposure, allowing machines to identify and extract stones with minimal human handling. Final inspection is carried out manually to verify quality and remove any remaining impurities.

This careful process ensures that only genuine rough diamonds move forward for cutting and grading.

Environmental Impact of Diamond Mining

Diamond mining has a substantial environmental footprint due to the scale and intensity of extraction activities. Open-pit and underground operations require the removal of large volumes of earth, which permanently alters landscapes and disrupts natural habitats.

Even after mining ends, land restoration is a long and complex process that does not always return ecosystems to their original state.

Water use is another major factor. Mining operations rely heavily on water for ore processing and dust control, which can strain local water resources. If not carefully managed, runoff and sediment can affect nearby soil and waterways.

Energy consumption is also significant, particularly in deep mining activity that relies on heavy machinery, ventilation, and continuous operation of cooling systems.

These environmental considerations have increased scrutiny on traditional mining practices and accelerated interest in more responsible and lower-impact diamond sourcing alternatives.

Alternative to Traditional Diamond Mining

Lab-grown diamonds present a commercially viable alternative to traditional diamond mining by eliminating the need for large-scale extraction operations. Produced in controlled laboratory environments that replicate natural formation conditions, these diamonds match mined stones in physical structure, chemical composition, and optical performance.

Beyond environmental benefits, lab-grown diamonds introduce meaningful operational advantages:

- Production is predictable and scalable, supporting consistent output without geological risks

- Reduced exposure to supply shortages, ensuring reliable availability

- Fewer geographic constraints, removing dependence on mining regions

- Lower market volatility, compared to finite natural deposits

This consistency enables tighter quality control, standardized specifications, and more reliable fulfillment across manufacturing and retail pipelines.

Cost efficiency is another key factor. Lab-grown diamonds typically involve lower input and logistics costs compared to mined diamonds, allowing for improved margin flexibility while maintaining certified quality standards.

Clear origin traceability also simplifies compliance, documentation, and ethical verification without reliance on complex mining supply chains.

As demand for transparent and responsibly sourced diamonds continues to grow, lab-grown diamonds support both commercial performance and long-term sourcing stability. They offer a practical path forward for businesses seeking consistent supply, competitive pricing, and alignment with evolving industry expectations.

Learn more about Lab-Grown vs Natural Diamonds!

Making A Smart Choice

Diamond sourcing today requires a balance of quality standards, supply consistency, traceability, and long-term value. Understanding how diamonds are mined provides important context, but modern supply chains increasingly prioritize alternatives that reduce operational risk while maintaining product integrity.

Lab-grown diamonds offer identical physical, chemical, and optical properties to mined diamonds, along with predictable quality, reliable availability, and transparent sourcing. Here are more reasons why choose lab-grown diamonds.

Controlled production removes dependence on finite natural deposits and minimizes variability, supporting scalable and consistent diamond supply across manufacturing and retail operations.

If sustainability, ethics, and value align with your sourcing priorities, explore Solitaire Lab Diamond’s collection of certified lab-grown diamonds. Connect with our team to review specifications, certification standards, and supply capabilities.

The diamonds you source reflect your standards. Choose one that reinforces trust, consistency, and long-term credibility.